One of the reasons for calculating the flow rate of your 3D printer’s flow rate is to tune it for speed. While accelerations and speed of the printer can be increased, a wall will be hit if the hot-end system is not capable of pushing enough plastic through the nozzle.

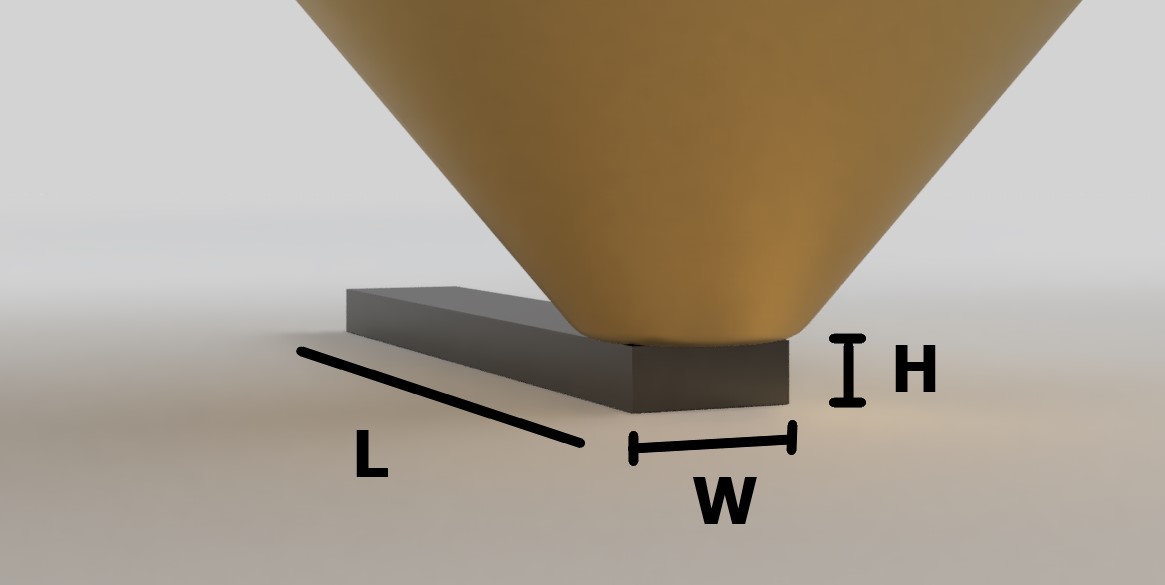

In its simplest form and in relation to 3D printing volume is measured by Length x Width x Height of the extruded line and it looks something like this:

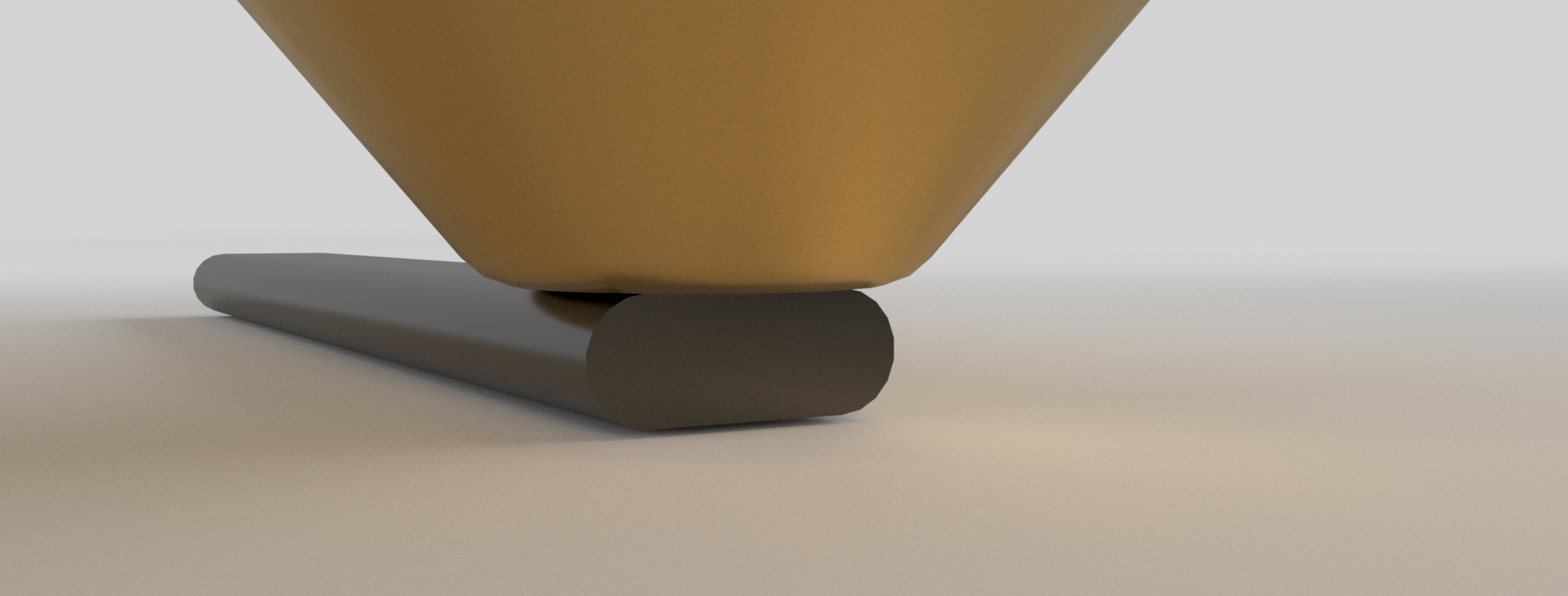

However, in reality, filament does not extrude in such blocky manner and it is not represented properly by a rectangular line as shown above. A more Accurate way to represent the extruded line is as below: (Please note the rounded edges of the line):

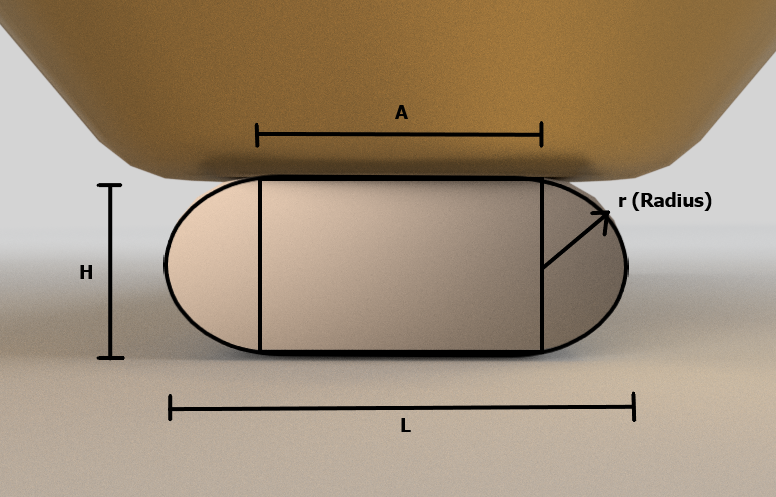

As such, a more accurate formula to take into account the rounded edge of this extruded line is something called a “stadium” formula which helps us compute first the area of this cross-section and then multiplying by the print speed in mm/s:

- A = length of straight side

- L = Overall length

- H = Height

- r = Radius

- π = Pi (rounded to 3.14)

Area of Stadium = π × r2 + 2 × r × a

Volumetric flow = Area of stadium (mm) x Speed (mm/s)

The difference between the volumetric flow rate formulas mentioned here is not that large but enough to make a difference.

Take for instance the following parameters:

Line width: 0.6(mm), Layer Height: 0.3(mm) and speed 100 (mm/s)

- Using the Line width x Layer Height x Speed = 18 mm³/s

- With the calculator on this page = 16.07 mm³/s

Thais a 2 mm³/s difference which can be significant if you’re pushing a stock hot-end on a typical 3D printer to its limit